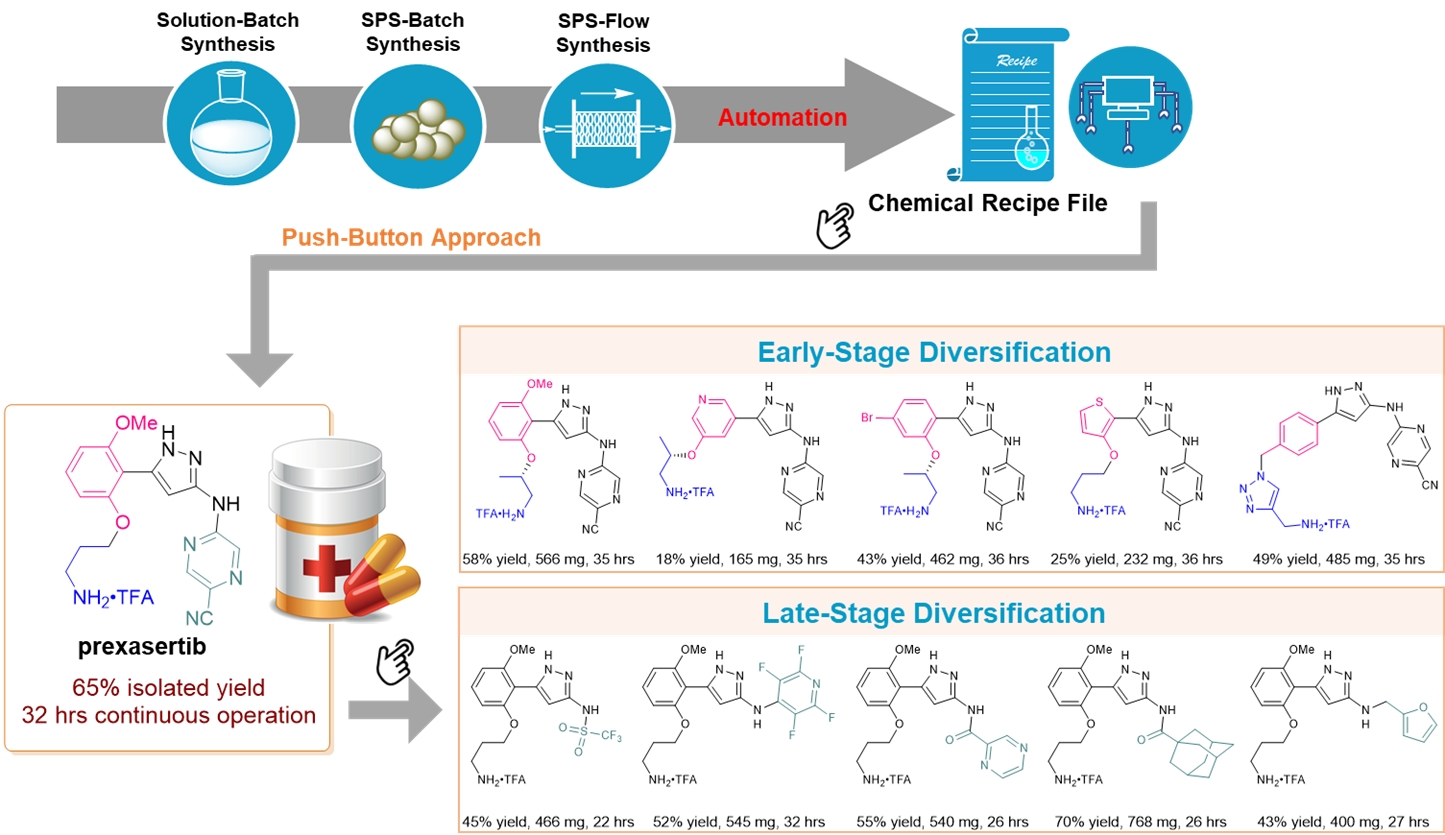

A research team led by Prof WU Jie, from the Department of Chemistry, National University of Singapore has developed an automated flow synthesis platform for the production of specific pharmaceutical compounds, prexasertib and 23 of its analogues, in a continuous and automated manner by combining two chemical synthesis techniques together. The first technique is continuous-flow synthesis in which chemical reactions are carried out in a continuously flowing manner rather than in batch production. The second technique is the solid-phase synthesis in which molecules are chemically bonded onto an insoluble support material and grown in a stepwise manner. In the new technique, known as solid phase synthesis-flow (SPS-flow), the target molecule is developed on a solid supporting material as the reaction reagent flows through a packed-bed reactor. The entire reaction process is automatically controlled by a computer-based chemical recipe file programmed using the LabVIEW software.

Prof Wu said, “Analysis of the top-selling 200 small-molecule pharmaceuticals indicates that automated SPS-flow synthesis could potentially be applied to a wide range of pharmaceutical molecules. However, there is still a long process before the SPS-flow synthesis can be applied in drug manufacturing and drug development. Future studies will target the development of a fully automated and portable system for API production at a larger scale which is more suitable for a manufacturing environment. It will also apply the SPS-flow technology in lead optimisation to speed up the drug discovery process.”

The figure above provides an overview of the workflow for the SPS-flow enabled automated synthesis of prexasertib and its derivatives. Through the computer-based chemical recipe file, the processing of the pharmaceutical molecule can be automatically controlled. It also allows for early-stage and/or late-stage diversification of the lead compound easily. Read the full story here.